Northtech, NT EM250 Linear End-Matcher

Description

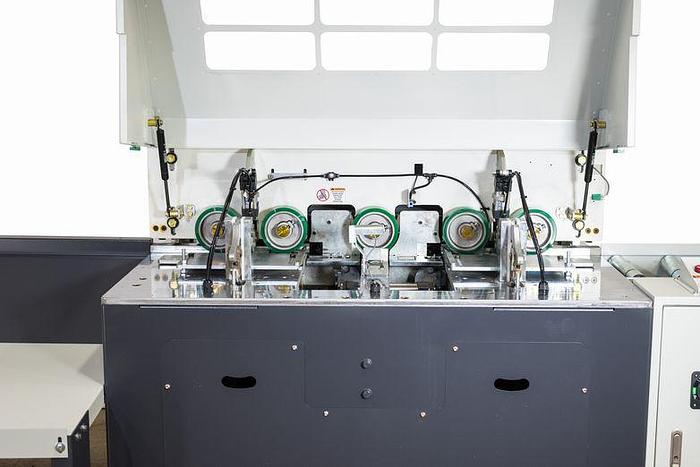

The NT-EM250 is our automatic 10″ working width feed through end matcher. The feed through design allows for simultaneously processing of both the tongue and groove end to two random length parts upon a single tool stroke. This provides an extremely efficient operation especially when connected to an automatic defect saw.

NT EM250 Linear End-Matcher MECHANICAL • Dual 5HP spindle motors 230, 3PH, 60 HZ • 12 CFM @ 90 PSI required • (1) 6” dust ports requiring 981 CFM @ point of extraction PRODUCT INFORMATION: • Width: 1-1/2” - 10” • Thickness: 3/8” - 1-3/8” • Length: 11” - unlimited • Maximum Weight of Lumber: 32lbs FEATURES: • 40mm spindles inside precision bearing • 1HP PLC controlled feed system manages spindles position, part location and both infeed and outfeed hold downs • Feed Speed: 80 - 400 FPM • Pancake style T & G heads, utilize carbide insert replacements for exacting repeatability (Included) • Dual lineal shaft guides for head movement • Touchscreen interface with production tracking • Chrome plated table • 134” Powered infeed and 88” outfeed • Infeed and outfeed with dual action clamping system with (5) powered urethane rollers • (3) Spring loaded bed rollers • FLR included • Fully automatic cycle operation • Processing speed: 75’ / minute *Based on 6’ material length • Net weight: 2,559 lbs. • Machine dimensions without infeed / outfeed: (L) 72" x (W) 33" x (H) 55" • Packing dimensions: (L) 78" x (W) 39" x (H) 63" • (1) Tool box • Warranty is one year parts • All machines are tested stateside prior to shipment providing trouble free start up.

Specifications

| Manufacturer | Northtech |

| Model | NT EM250 |

| Condition | New |

| Stock Number | NT EM250 |

| MAIN MOTOR HP | (2) 5 HP Motors |

| VOLTAGE, FREQUENCY | 230/460 Volt 60Hz |

| PHASE | 3 Phase |

| AMP REQUIREMENT | 19.5 / 39 Amps |

| 1ST STATION | Tongue |

| 2ND STATION | Groove |

| SPINDLE LENGTH | 5'' |

| SPINDLE DIAMETER | 40 MM |

| SPINDLE RPM | 7410 rpm |

| FEED SYSTEM | (4) Feed Wheels |

| DRIVE SYSTEM | Gear Driven |

| FEED SPEED RANGE | 80 - 400 FPM |

| VARIABLE FEED SPEED | Inverter Controlled |

| TOTAL MACHINE HP | 12.5 hp. |

| APPROVED ELECTRICAL PARTS | CE Approved Components |

| CONTROL VOLTAGE | 24 Volt |

| TOUCH SCREEN | 5-1/2'' Touch Screen |

| PASS-LINE | 35-3/4 |

| MIN. WORKING LENGTH | 10.63'' |

| MIN. WORKING WIDTH | 1-1/2'' |

| MAX. WORKING WIDTH | 10'' |

| MIN. WORKING THICKNESS | .393 |

| MAX. WORKING THICKNESS | 1.375'' |

| DUST PORT SIZE OUTLET | (1) 6'' Port |

| CONVEYOR | Powered Infeed Conveyor |

| IDLE ROLLERS | (3) Idle Bed Rollers |

| TOTAL CLAMPS | (2) Clamps |

| FLR INCLUDED | Filter, Lubricator, Regulator |

| EMERGENCY STOP | Push Button |

| GUARDING | Full Cabinet Enclosure |

| OPERATION STYLE | Touch Screen Control |

| FENCE TYPE | Fixed Fence |

| FRAME CONSTRUCTION | Steel Construction |

| WORKTABLE DIMENSIONS | 23-1/2'' x 55-1/4'' |

| TABLE CONSTRUCTION MATERIAL | Steel |

| INFEED TABLE LENGTH | 133-1/2'' Infeed |

| OUTFEED TABLE LENGTH | 87-1/2'' Outfeed |

| CHROME BED PLATE | .004'' Chrome Plated Bed |

| MEASURING METHOD | Precision Encoder |

| AUTO CYCLE | Yes |

| DECIBEL RATING | 76 dB |

| NET WEIGHT | 2559 Lbs. |

| GROSS WEIGHT | 2734 Lbs. |